Iron foundry basics

Practical Action

Metal can be run from a cupolette into ladles from

which it is poured into the moulds.

An uninterrupted pour into each mould is essential to

ensure no discontinuity in the final casting. If the size

of the casting is such that one ladle's contents are not

sufficient, a second ladle of molten metal must be

available. Pieces of slag found floating on the metal

should be skimmed off before the metal is poured into

the mould. Normally those who tend the furnace also

pour the metal into the moulds.

Safety

This is a major consideration. Protection for head,

eyes, feet, legs and hands is essential, and the

discipline of those handling the metal is equally

important.

Knocking Out and Fettling

However accurately the moulds have been made,

castings will require cleaning and trimming before

they can be passed on for other operations, such as

immediate use, or machining.

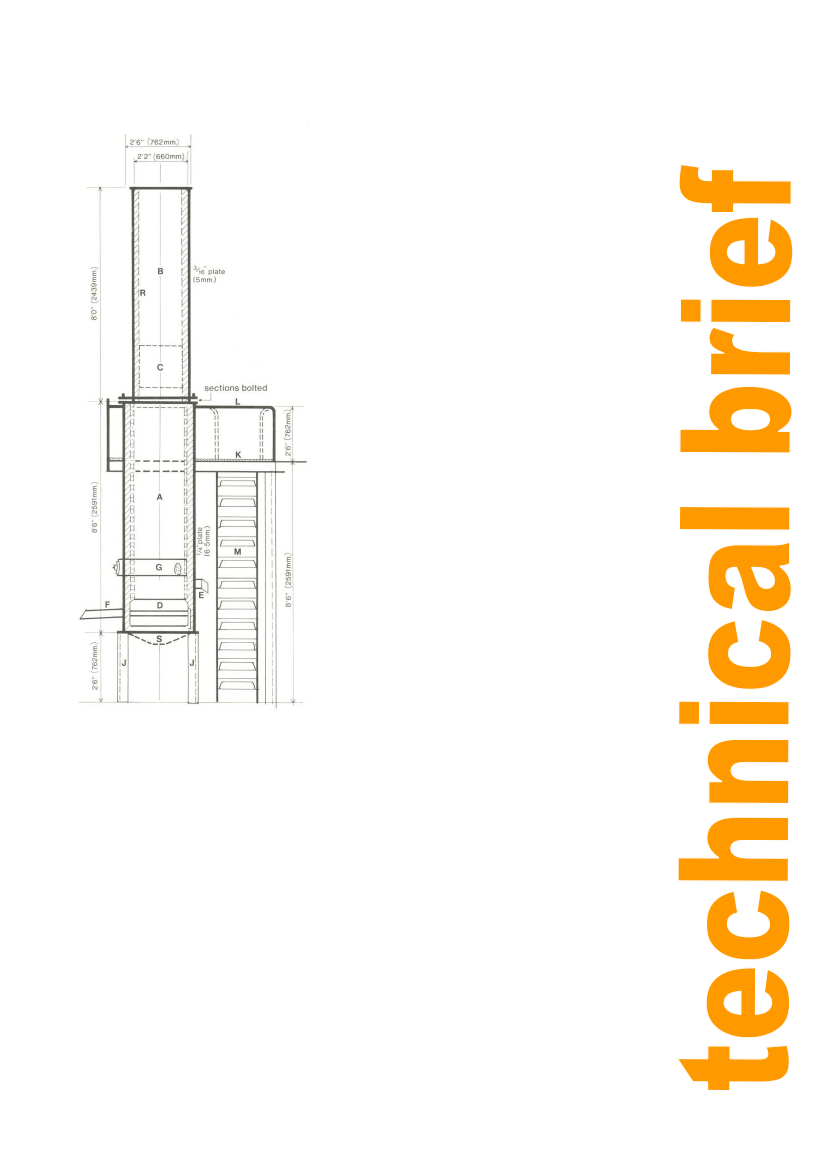

Figure 6: Cupolette View on arrow A

When the castings have cooled off, they are removed

from the moulds. Any sand or clay is cleaned from the

castings. This is done by rapping the casting with a

light hammer and finishing off with a wire brush.

Surplus iron pieces, such as runners and risers are

knocked off (Fig 9) and any irregularities at the mould

joints are trimmed with a file or grindstone.

The amount of fettling required depends on the quality of the mould, and the customer's

requirements.

Equipment Required (Fettling)

Light Hammers

Files - various shapes, i.e. flat, half round, round etc.

Chisels

Wire Brushes

Goggles - for fettlers

These can normally be obtained from local purchase.

As far as foundry work is concerned the product has now passed throuqh all stages for completion.

It is necessary however for the articles to be inspected, to detect any flaws or errors in the castings

that could affect the use for which they are intended. Any rejects are returned to the furnace area

for future melts. Those that pass the inspection are ready for sale.

8